Building for the AI Era: How Fab Expansion and Data Center Growth Are Reshaping Semiconductors

17 Feb 2026

The AI Boom Is Driving a New Semiconductor Reality

The semiconductor industry has entered a transformative phase. Historically defined by cyclical booms and busts, the market is now experiencing sustained growth fueled by artificial intelligence (AI). Data center servers that are critical for training and deploying large-scale AI models have become the dominant driver of semiconductor revenue. This surge is creating unprecedented demand for GPUs, advanced logic chips, high-bandwidth memory (HBM), and power management ICs.

Data processing applications are on track to surpass 50% of total semiconductor revenue for the first time, with hyperscalers leading massive infrastructure investments. Edge AI is also gaining momentum, pushing demand for specialized chips in automotive, industrial, and consumer devices.

Fab Expansion: From Caution to Aggression

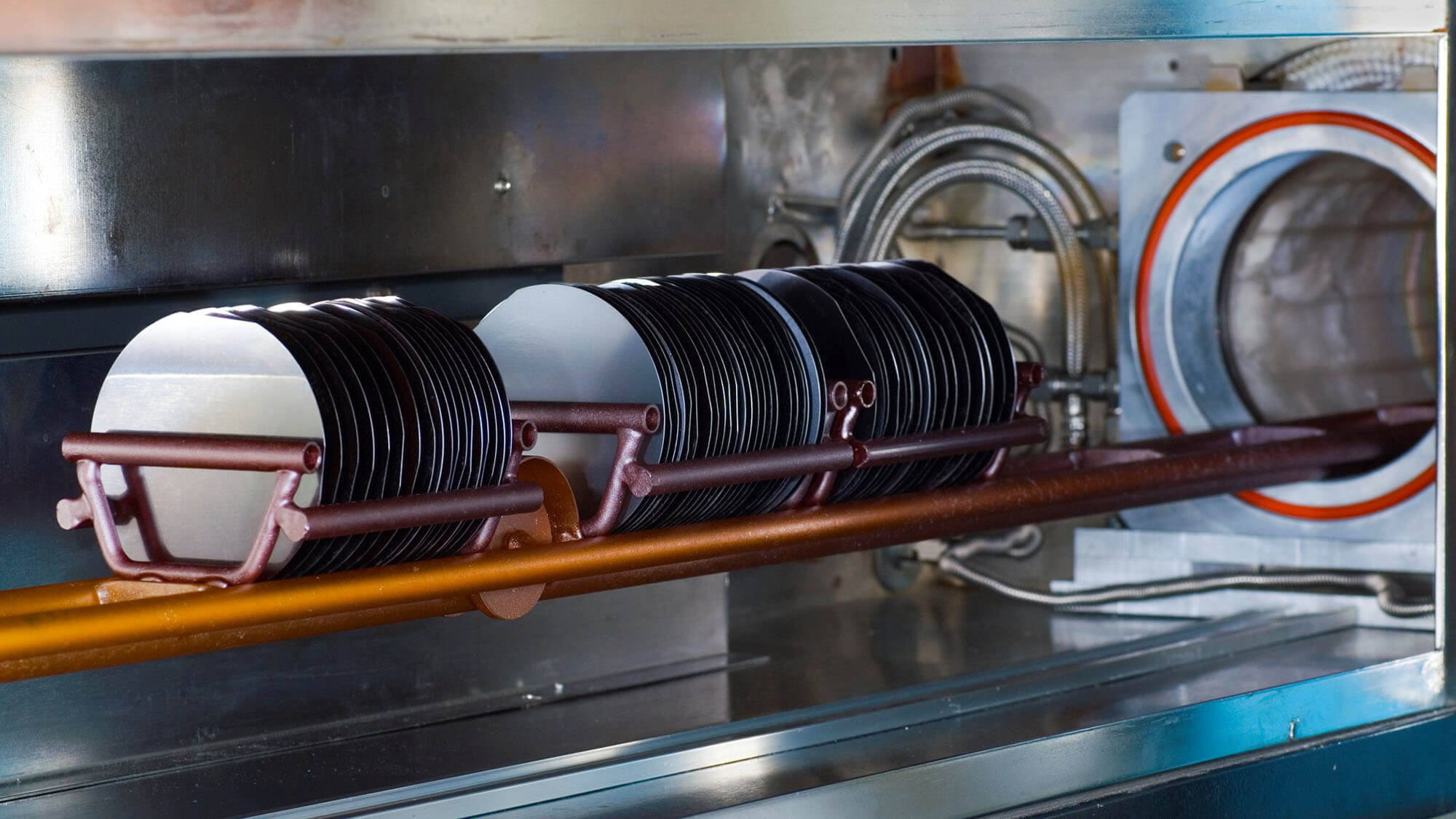

To meet this demand, integrated device manufacturers (IDMs) and foundries are shifting from cautious capacity planning to aggressive expansion. After years of restrained spending, forecasts for 2026 expect to see record capital expenditures and wafer capacity growth across logic, memory, and discrete components. Memory ICs (especially DRAM and HBM) are at the center of this investment wave, with large manufacturers prioritizing advanced stacking technologies and sub-1nm nodes.

This expansion isn’t limited to traditional hubs. Global initiatives like the EU Chips Act and U.S. CHIPS Act are incentivizing new fabs, diversifying supply chains, and reducing geopolitical risk. These megaprojects face challenges: infrastructure bottlenecks, power grid limitations, and sustainability concerns could slow progress if not addressed proactively.

The Ripple Effect: Power, Cooling, and Sustainability

The AI-driven data center boom brings more than silicon challenges. Facilities require massive power and advanced cooling systems to support high-density compute clusters. Energy efficiency and environmental compliance are becoming critical differentiators for semiconductor companies and their partners. As fabs scale and data centers proliferate, sustainability will move from a corporate goal to a regulatory mandate.

How Intertek Can Help

Intertek is uniquely positioned to support this next wave of semiconductor growth:

- SEMI Standard Servies: Many fabs require compliance with the SEMI S-series standards in addition to the regulatory requirements for the country. Intertek offers a wide range of semiconductor equipment services including SEMI S2, S8, S10, etc., evaluations.

- Equipment Inspection and Certification: Intertek’s global footprint allows for our local experts to assist manufacturers with meeting their regulatory requirements. Intertek’s Field Evaluation program is well suited to address specially designed fabrication equipment intended for U.S. fabs. Our experts can also provide ETL listings services for Canadian and U.S. markets, as well as conformance with EU Directives and Regulations.

- Datacenter Services: Hyperscalers have a variety of challenges upcoming, meeting regulatory requirements and maintaining strong supply chains. Intertek provides datacenter services across all stages of design, construction and commissioning of new datacenters.

- Cybersecurity & Asset Integrity: Protecting critical infrastructure from physical and digital threats.

- Global Expertise: Leveraging a worldwide network to streamline compliance and certification across multiple regions.

Final Thoughts

The convergence of AI-driven demand and aggressive fab expansion marks a defining moment for the semiconductor industry. Companies that can scale responsibly by balancing speed with compliance, quality, and sustainability will lead the next era of innovation. Intertek stands ready to help semiconductor leaders navigate this complex landscape with confidence.